Cox & Company has the ability to design and manufacture composite parts utilizing both fiberglass and carbon fiber fabrics in conjunction with numerous resin systems.

Highlighted equipment includes:

- 2,000ft² Contamination Control Area for Layup

- AVS Autoclave 4’ Ø x 11’/1.2 x 3.3m,500°F/150psi

- ACS Autoclave 5’ Ø x 16’/1.5 x 4.9m, 450°F/150psi

- Thermwood Model 77 5-Axis CNC Machining Center 10' x 5' x 3'

- Gerber Cutters 12’ x 6’/3.6 x1.8m cutting surface

- Heated Presses up to 8’ x 4’/2.4 x 1.2m in size

- Paint Booth

- Multiple Ovens

Cox & Company has the ability to design and manufacture avionics using traditional through-hole, mixed-component, and the latest SMT technologies.

Highlighted equipment includes:

- SMT Pick-and-Place (MyData M100)

- Reflow Oven (Heller MKIII 1707)

- Contact System Cut and Cinch (CS400)

- Selective Solder (KISS-103)

- De-flux/Cleaner Aqueous Tech (Trident ZDG)

- Automated Optical Inspection (Marantz M22XFDAZ-250)

- PVA Delta 8 Conformal Coating Machine

- Komax Kappa 320 Cut and Strip Machine

Cox & Company has the ability to design and build tooling to support its system and structural component manufacturing, as well as select metal sub-assemblies.

Highlighted equipment includes:

- Haas Vertical Machining Center 84” x 32” x 30”, 30HP

- Numerous lathes, cutting tools, drill presses, etc.

- Engineering Prototypes

- Test Fixtures

- Low volume production runs

- Tooling

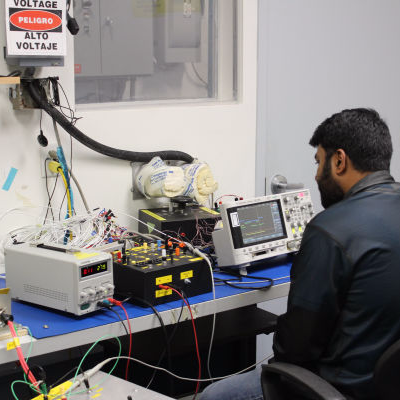

Cox & Company has numerous internal test facilities to support the design, development, and qualification of its system solutions.

In addition to the list below, Cox maintains strong relationships with local test laboratories for qualification related activities.

Highlighted equipment and facilities include:

- LIRL Icing Wind Tunnel

- Icing Wind Tunnel Model Fabrication / Prototype Shop

- Highly-Accelerated Life Testing (HALT) chamber combined temperature and vibration

- Vibration Table LDS, 3,000lb/1,360kg slip table

- EMI Compliance Laboratory

- X-ray machine

- Multiple Environmental Chambers