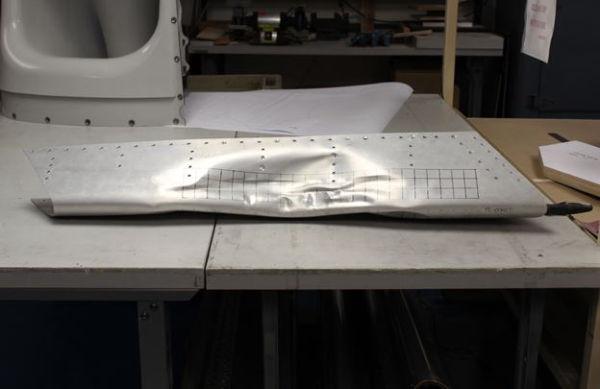

- Certified bird strike protection for FAR Part 25 and Military aircraft

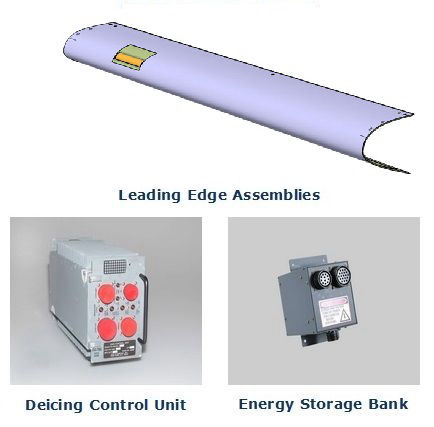

- Cox's Low Power Ice Protection Systems are combined with custom-designed birdstrike protection strategies

- Provides significant weight, cost, and supplier management savings

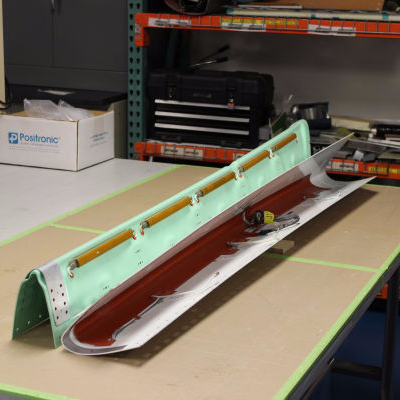

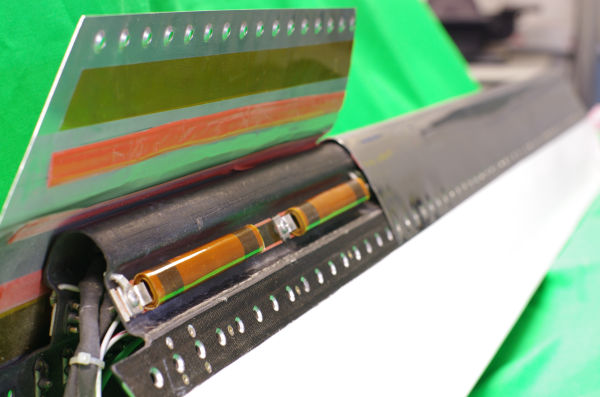

EMEDS is a proven ice protection alternative to pneumatic or electrical deicing boots on leading edges. EMEDS achieves reduced airfoil drag and surface erosion characteristics - while also improving deicing performance and aircraft aesthetics.

The newest Low Power Ice Protection System offered by Cox, TMEDS builds upon the proven history of EMEDS and provides bleed-air / electro-thermal equivalent ice protection on leading edges at a fraction of the power.

When continuous anti-ice performance is required with limtied available power, Cox's Hybrid systems combine its electro-thermal anti-icing and EMEDS technologies to provide an optimum solution

| Parameter / System | EMEDS | TMEDS | Pneumatic Boots | TKS | Electro-Thermal |

|---|---|---|---|---|---|

| BITE & Fault Reporting | Isolates to sub-component | Isolates to sub-component | High-level / Wing-only | High-level / Wing-only | Isolates to zone |

| Erosion Surface Material | Metal or Composite | Metal or Composite | Elastomeric | Titanium | Metal or Composite |

| Erosion Surface Life | Life of aircraft | Life of aircraft | Months to approx. 5 years depending on service | Life of aircraft | Life of aircraft, depending on service |

| Drag Increment | No increase | No increase | Measurable increase | Minimal increase | No increase |

| Deicing Performance | As low as 0.050" & no upper limit | Frost & no upper limit; bleed air-like performance after exiting icing | Typically greater than 0.25" | Anti-ice system. Must be activated prior to icing encounter to be effective. | Requires parting strip, creates runback ridges |

| Weight | Baseline | Slightly greater than baseline for system hardware | Equivalent | System hardware is equivalent, plus additional 55 lbs (avg) for fluid | Less than or up to equivalent; dependent upon electrical generator |

| Cost (USD) | Baseline | Greater than baseline | Equivalent | Equivalent + $100/flight (@ 8 gallons / 2.5 hrs) | Equivalent, not including electrical generator |

| Power (42' span) | 300W | 2300W | (up to) 775W (1 HP from engine for deflation / inflation + 28W electrical power for control) | 42W (for pumps and control) | >20,000W |