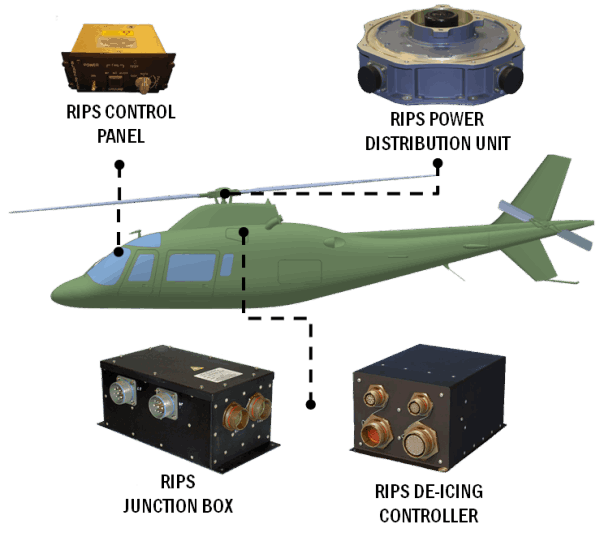

Rotorcraft Ice Protection System (RIPS)

Deicing the main and tail rotor blades is essential to maintaining safe flight operations in natural icing conditions. Cox & Company's RIPS avionics suite is qualified and ready for introduction into additional rotorcraft with minimal modifications required.

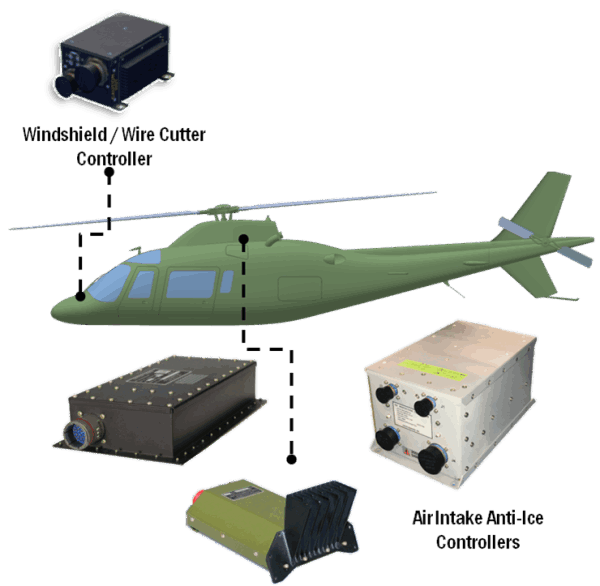

Electronic Controllers for Windshields, Inlets, Fairings, & Other Heated Components

Proportional power control with fault detection, reporting and diagnostic test capabilities in ruggedized packages to meet harsh environments in engine nacelles and on exposed fairing surfaces.

Controllers are typically used to control heaters in engine intakes, windshields, fairings, scoops and other components for anti-icing, deicing, and defogging applications.

Inlets, Fairings, & Scoops

Each design contains custom-designed heating circuit layouts with tailored Watt densities to match icing or snow loads in specific heated zones to minimize total power consumption. These thermal designs are developed using Cox proprietary and NASA Icing Codes and validated with the Cox Thermal Test Management Systems (TTMS) and the LeClerc Icing Research Laboratory (LIRL).

Rotor Blade Heaters

Cox has designed and developed a next generation rotor blade heater using its ThermoWire technology that can be readily adapted for use on all existing and new rotorcraft.

-Comparable cost to existing heaters on the market

-Fatigue life greater than 10,000,000 strain cycles

-Direct replacement for existing heaters possible

-100% compatible with existing electrical interfaces

-No tooling changes necessary at the OEM level